Industries we support

Our Product Range

NEMpreg

NEMpreg is an advanced pre-impregnated composite fiber that features a one component, snap epoxy resin which is curing at a low temperature in a shorter time and can be stored at room temperature.

120°C / 7 min

Snap cure resin that processes at 120°C in only 7 minutes

> 12% flow

Prefect adhesion with stable resin flow above 12%

30% faster

overall production time thanks to all features

2 months

maximum storage at room temperature

NEMresin

NEMresin is a powdered snap cure epoxy resin which can be stored at room temperature. It liquifies when subjected to an increase in temperature and hardens rapidly.

Powdered

single-component, epoxy resin with simple and short manufacturing process

Liquifies

at 65-80°C and cures at 90-120°C, afterwards the resin hardens rapidly

Award winner

in process innovation at AVK Composite Europe

6 months

maximum storage at room temperature

NEMplate

Carbon or glass NEMplates are manufactured under heated pressure from multiple layered NEMpregs (based on carbon or glass uni-directional or twill fiber impregnated with epoxy resin).

Properties

excellent dielectric and mechanical properties, non-corrosive

Reinforcement

material range from Glass-Fiber, Carbon-Fiber to Hybrid and Flax

Possible mix

in the plate

Large sizes

up to 1000 x 2000 mm sheets and 1-10 mm thickness

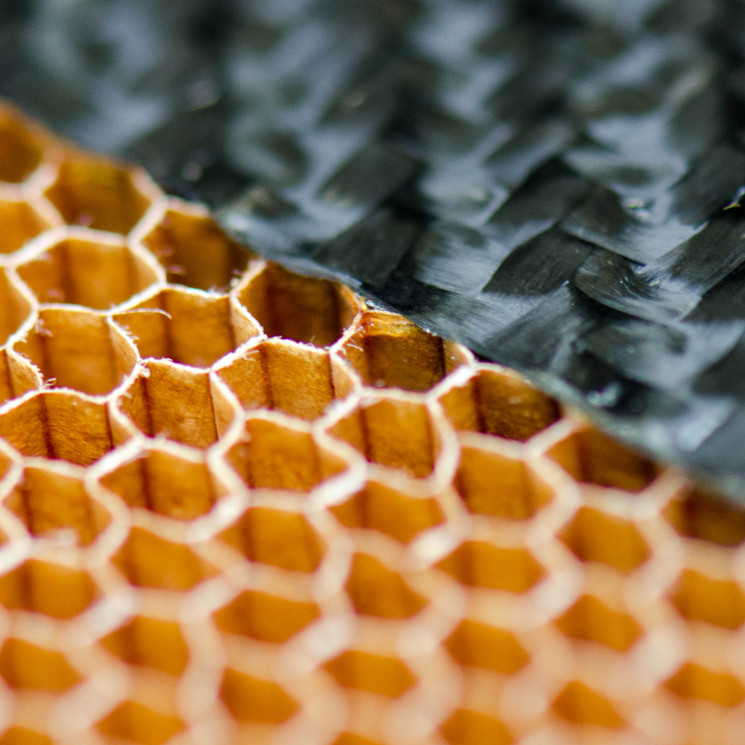

NEMsandwich

Composite panel where various core materials can be integrated to create smart structures. There is a wide range of mechanical properties that can be customized and effectively used.

Integration

of various mechanical and electronical inserts, such as LED, sensors & circuits

Reinforcement

material range from Glass-Fiber, Carbon-Fiber to Hybrid and Flax

Custom core

materials to choose from, like Honeycomb and Foam

Large sizes

up to 1000 x 2000 mm sheets and 30 mm thickness

NEMcomposites

NEMcomposites is a division of New Era Materials responsible for composite 2D and 3D spatial elements production. By using our modern and patented Resin Powder Moulding / Thermoset Sheet Forming technology and snap cure epoxy NEMresin, we are able to reduce the productions process time to 8 minutes, increase speed up to 30% above industry standards and provide the confidence of full control over resources, quality and costs.

Smooth

surfaces and high quality internal structures guaranteed by closed mould pressing

Start in 48h

of producing composite elements thanks to NEM-developed Rapid Composite Forming (RCF)

Latest Highlights

NEMpreg.BIO7540

NEMpreg.BIO7540 – aesthetics on a new level. Discover the innovative possibilities offered by NEMpreg.BIO7540 – the latest prepreg developed by the New Era Materials R&D Team. This material redefines the approach to esthetics in composite technology, offering designers of modern products a combination of high-quality finish, excellent performance and a sustainable composition from responsible sources. NEMpreg.BIO7540 has been designed…

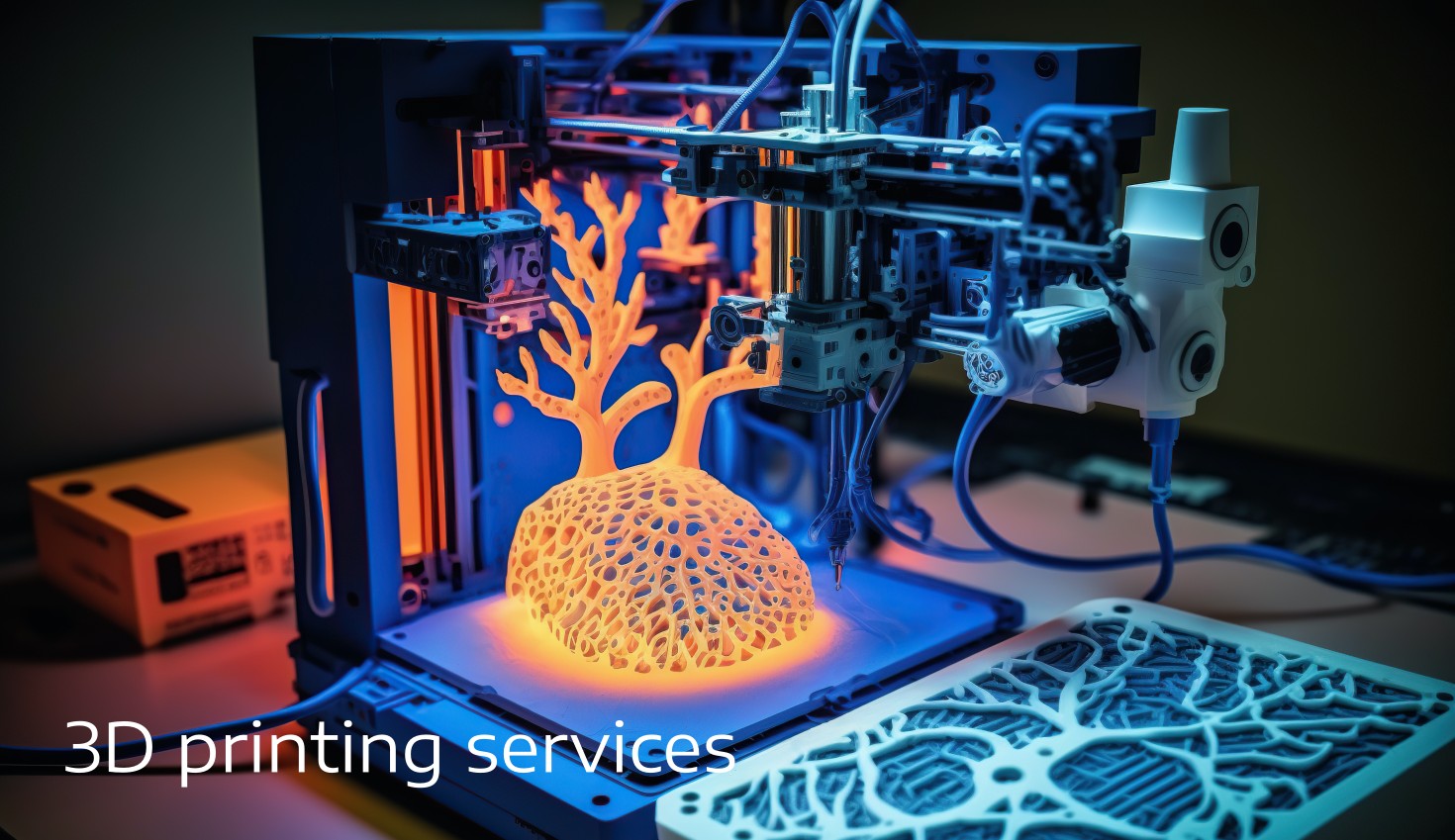

Industrial 3D printing in development and mass production for the Defence Industry.

The defence industry is currently at a turning point – increasing technological demands, the need to respond rapidly to emerging threats, and growing pressure to improve the efficiency of design and production processes are all driving the sector to embrace innovative solutions. Additive technologies, such as industrial 3D printing, along with advanced composite materials, are…

Composites and 3D Printing in the service of defense – IDET 2025

In recent days, we had the opportunity to attend the IDET 2025 international trade fair in Brno – one of the most important events in Central Europe dedicated to defense and security technologies. This year’s edition brought not only impressive displays of military equipment but also a clear message: modern materials and technologies, such as…

NEMpreg.BIO7540 is now part of NEM lineup! A new chapter in the history of composite materials.

Is it possible to combine excellent mechanical properties with genuine concern for the environment? At NEM, we say: definitely yes! We are proud to present NEMpreg.BIO7540 – the latest product in our innovative line of BIO-prepregs, developed specifically for the sports industry. This advanced material contains at least 20% bio-based components, while offering technical performance…

BALTIC MILTECH SUMMIT – 7 May 2025

We’re proud to be present at the Baltic Miltech Summit 2025 in Vilnius – a unique convergence point for defence innovators, NATO representatives, and cutting-edge technology providers shaping the future of European and transatlantic security. This event isn’t just about showcasing new products – it’s about rethinking the role of materials science in defence strategy. The battlefield…

DEFEA 6 – 8 May 2025 – Greece

🔰 Shaping the Future of Defence Materials at DEFEA 2025 🔰 Representatives of New Era Materials are present at DEFEA – Defence Exhibition Athens 2025, one of Europe’s leading defence industry events, bringing together top-tier manufacturers, technology innovators, and government stakeholders. As the modern battlefield evolves, the demand for lightweight, durable, and multifunctional materials continues to rise….