- Home

- About

About Us

New Era Materials was established in 2012 on the basis of a breakthrough technology of one-component powdered resin in order to develop innovative solutions for the production of components and composite elements. For its invention – the composition of reactive epoxy resins and the method of producing products pre-impregnated with the composition of reactive epoxy resins, the Company has three patents: Polish, European and US, including the last two enriched with the production of preg and ready-made composite elements.

The company’s mission is to carry out the advanced R&D works in order to introduce process and product innovations that allow us to deliver composite materials of the highest quality by developing automatic productiontechnology for composite components and elements. NEM’s flagship products are NEMresin powdered epoxy resin systems for the production of NEMpreg pre-impregnated materials and ready-made composite parts,including custom-made materials. The main recipients of NEM products are manufacturers of sports goods, vehicle parts, structural elements or companies dealing in the repair of composite structures.

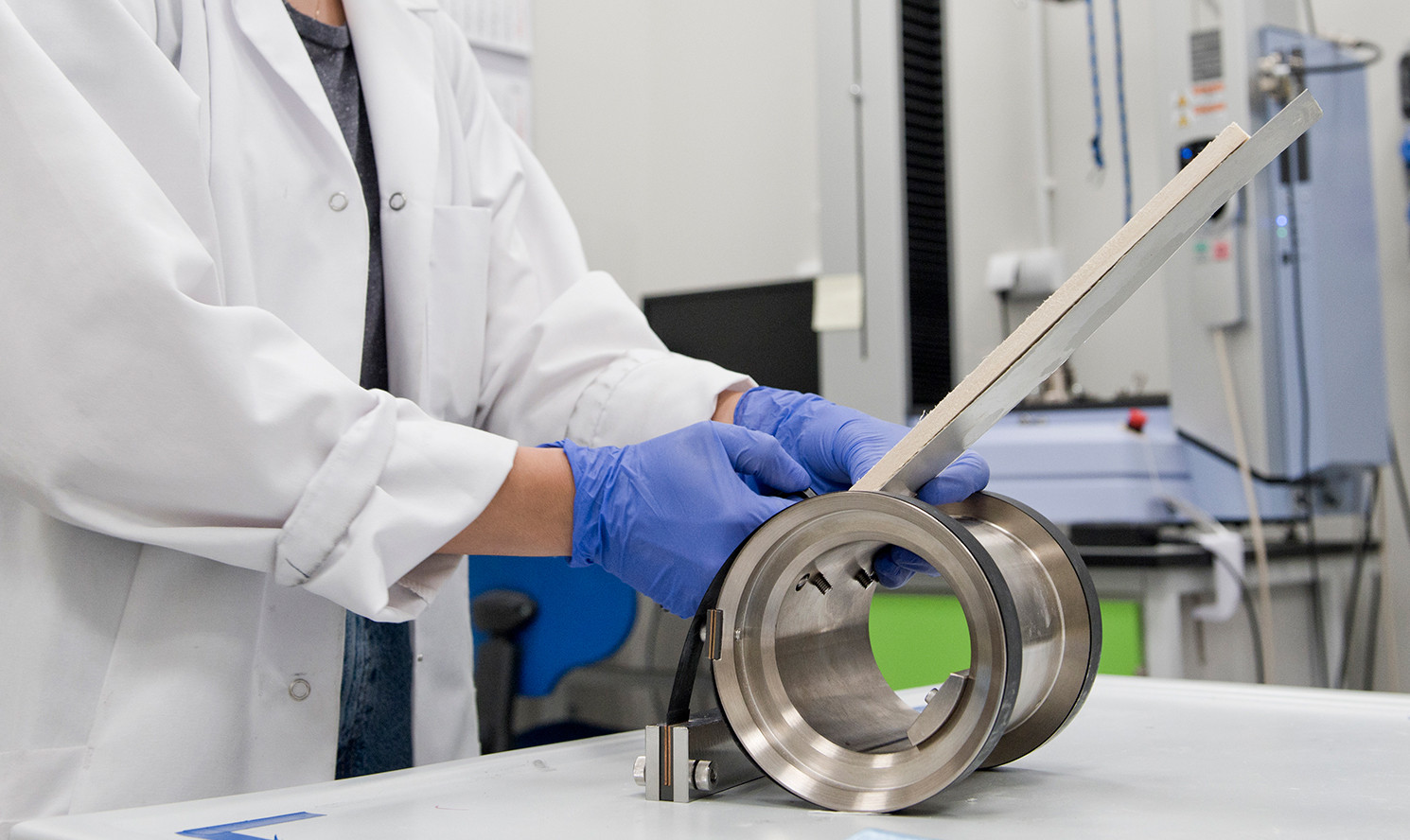

Currently, NEM employs about 100 employees and has a well-equipped laboratory and production plant in Modlniczka, where it carries out research, develops NEM technologies and products.NEM’s laboratories cover 5 main areas: material synthesis and modification, thermal analysis and rheology, mechanical tests, flammability tests, and accelerated aging tests.

Life Cycle Assessment

At New Era Materials, we recognise that a superior product is not solely defined by its intrinsic material properties. We also consider the contribution we make to future generations. To that end, we have established a comprehensive approach to product development.

New Era Materials was established in 2016 near Cracow. From the outset, our mission was to create materials that are as safe as possible for people and the environment. We have chosen to locate our facility in the Natura 2000 area, which aligns with our core values. We have chosen the components for production responsibly, using only solvent-free solutions, and manufactured mainly in the EU.

Moreover, we ensure that almost 100% of our energy is made by renewable energy sources. In the next years of our expansion, we will focus on implementing new technologies and products concerning the adopted assumptions. On the one hand, we will reduce the energy needed for the manufacturing of both prepregs by lowering process temperature and composites by shortening the curing cycle. On the other hand, we develop resin systems with bio-based carbon raw materials or apply natural reinforcements.

NEW ERA MATERIALS are created with awareness of the environmental impact.

In everyday activities, we consider sustainability to limit the carbon footprint in purchasing, storage, production, shipping, and waste reduction. We attend exhibitions on sustainability topics to better understand our responsibilities and learn about LCA. Only through strong collaboration, as part of a sustainable organisation, can we make our world a better place to live.

What are epoxy resins?

Epoxy resins are most important thermosetting polymers thanks to their excellent chemical, mechanical, thermal and adhesive properties. Epoxy resin is a polymer that contain the epoxide group (also known as ethoxylene or oxirane), in which an oxygen atom is bonded to two adjacent (end) carbon atoms.

Epoxy resins cure or set into a hard shape using curing method such as heat or radiation. The curing process is irreversible since a polymer network is crosslinked by covalent chemical bonds. The crosslinking of epoxy resin can be the result of an addition or homopolymerization reaction.

How we solve problems?

Difficulties, problems, issues and challenges

During product development businesses might find themselves in a situation where they face with a seemingly impossible challenge. When such cases occur, the best is to discuss it with someone who has also faced the same or similar challenges during product development or design. Our advanced team gives you a helping hand and decades of experience to solve your problems, issues and overcome your challenges.

Consulting about the possibilities with our experienced specialists

During consultation we help you to find solutions to your design, technical, productional, processing or finishing problems. We offer you not only the technical support, but also sharing the know-how and giving you an advice for selecting materials, production technologies, machinery and software background. Our consulting service offers you a tailored solution to your exact need, keeping in mind effectiveness, productivity and cost-relations.

Finding the best solution, testing and implementing it

After finding a technical, production or design solution to your problem, we give you advice on the possible options and letting you choose the most ideal one. Afterwards we run the solution through various tests and optimalise the process to suit all your requirements and needs. Our scientists and experts diligently search for areas of methods that can be made faster and better for your benefit.

Developing the solution for large-scale manufacturing

When the testing is done and successful, we help you to install the chosen hardware and software, put tested processes into action on a large scale. We monitor the first full production lines to detect the effectiveness of your processes in reality. We also give you advice on training employees to carry out tasks that are necessary to maintain a high workflow standard.

In the center of our history there is science.

2012

Establishment of NEM and decision to commercialize research results.

2013

Inventing a new system for the production of epoxy resins that enables the production of composites quickly and in technologically uncomplicated way.

2014

AVK Innovation Award of Composite Europe, Düsseldorf. NEM has signed a framework cooperation agreement with Leichtbau-Zentrum Sachsen GmbH (LZS) in Dresden.

2015

The Michał Sołowow Group has become a strategic investor of NEM. The company becomes a finalist of the Orzeł Innowacji 2015 competition (Rzeczpospolita).

2016

Relocation of NEM from Szczecin to a new headquarters in Modlniczka near Cracow (new plant, approx. 3,900 m2). NEM’s technologies were awarded at Kompozyt-Expo in Cracow.

2019

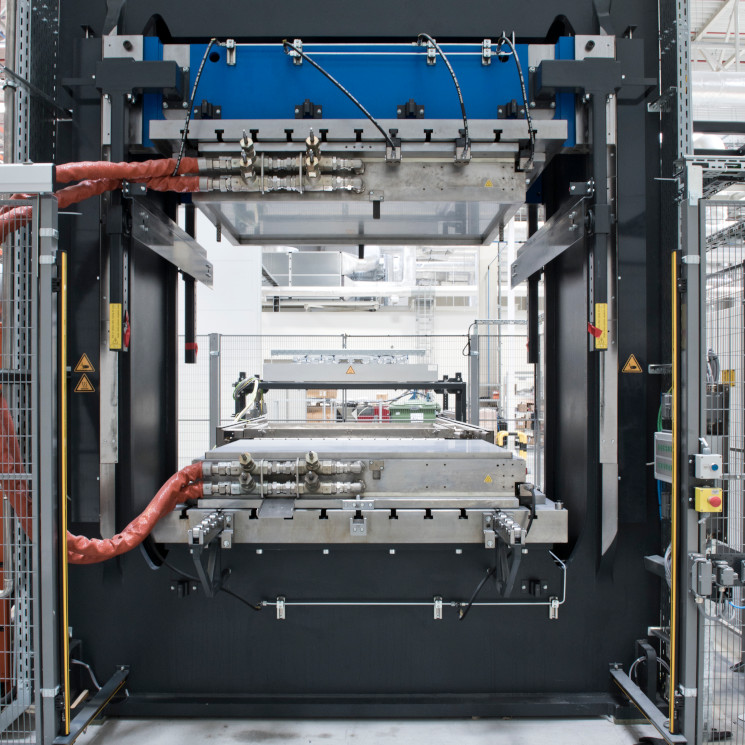

Investment in new high-technology production line for prepregs and composites press system.

A successful certification by Windguard Certification GmbH.

2020

Our subsidiary structrepair GmbH awarded DNV-GL certificate for the epoxy prepreg based composite repair solution.

2021

We work in accordance with the guidelines of the ISO 9001 and 14001 quality systems, which confirm the quality of our services and products. View our ISO certificates.

2023

New Era Materials is awarded a licence by the Ministry of the Interior and Administration (MSWiA) to supply products for the defence industry. No B-O75/2023.

Our Corporate Achievements

66M PLN

5

27

17

30

Our Work Stations

Interested in cooperating? Get in touch.

Latest Highlights

New Era Materials at MSPO 2025 in Kielce! On 2–5 September 2025, we invite you to visit our stand 2-C05 during the 33rd Edition of the International Defence Industry Exhibition MSPO at Targi Kielce – one of the largest arms industry trade fairs in Europe. MSPO is a unique event that brings together manufacturers and…

Advanced Aramid-Based Prepreg – Solutions for the Defence Industry

Composite materials are playing an increasingly important role in modern defense industries especially in applications where structures must combine high strength with low weight and resistance to extreme conditions. Among these, epoxy-based prepregs stand out as key solutions. Thanks to the precisely controlled distribution of resin across the entire fabric surface, they ensure structural uniformity,…

NEMpreg.BIO7540

NEMpreg.BIO7540 – aesthetics on a new level. Discover the innovative possibilities offered by NEMpreg.BIO7540 – the latest prepreg developed by the New Era Materials R&D Team. This material redefines the approach to esthetics in composite technology, offering designers of modern products a combination of high-quality finish, excellent performance and a sustainable composition from responsible sources. NEMpreg.BIO7540 has been designed…

Industrial 3D printing in development and mass production for the Defence Industry.

The defence industry is currently at a turning point – increasing technological demands, the need to respond rapidly to emerging threats, and growing pressure to improve the efficiency of design and production processes are all driving the sector to embrace innovative solutions. Additive technologies, such as industrial 3D printing, along with advanced composite materials, are…

Composites and 3D Printing in the service of defense – IDET 2025

In recent days, we had the opportunity to attend the IDET 2025 international trade fair in Brno – one of the most important events in Central Europe dedicated to defense and security technologies. This year’s edition brought not only impressive displays of military equipment but also a clear message: modern materials and technologies, such as…

NEMpreg.BIO7540 is now part of NEM lineup! A new chapter in the history of composite materials.

Is it possible to combine excellent mechanical properties with genuine concern for the environment? At NEM, we say: definitely yes! We are proud to present NEMpreg.BIO7540 – the latest product in our innovative line of BIO-prepregs, developed specifically for the sports industry. This advanced material contains at least 20% bio-based components, while offering technical performance…