- Home

- Laboratory

“Nothing in life is to be feared, it is only to be understood” – Maria Skłodowska-Curie

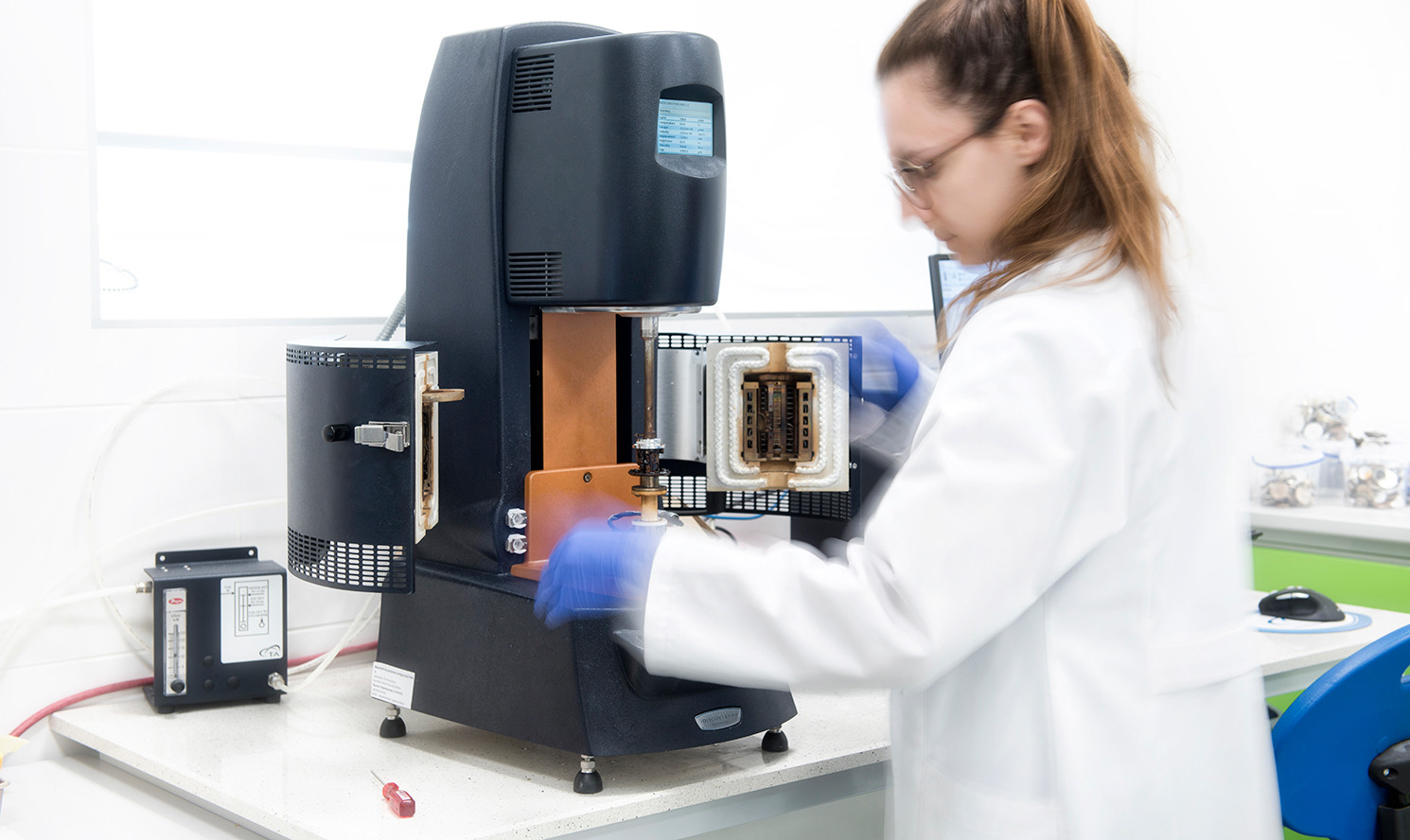

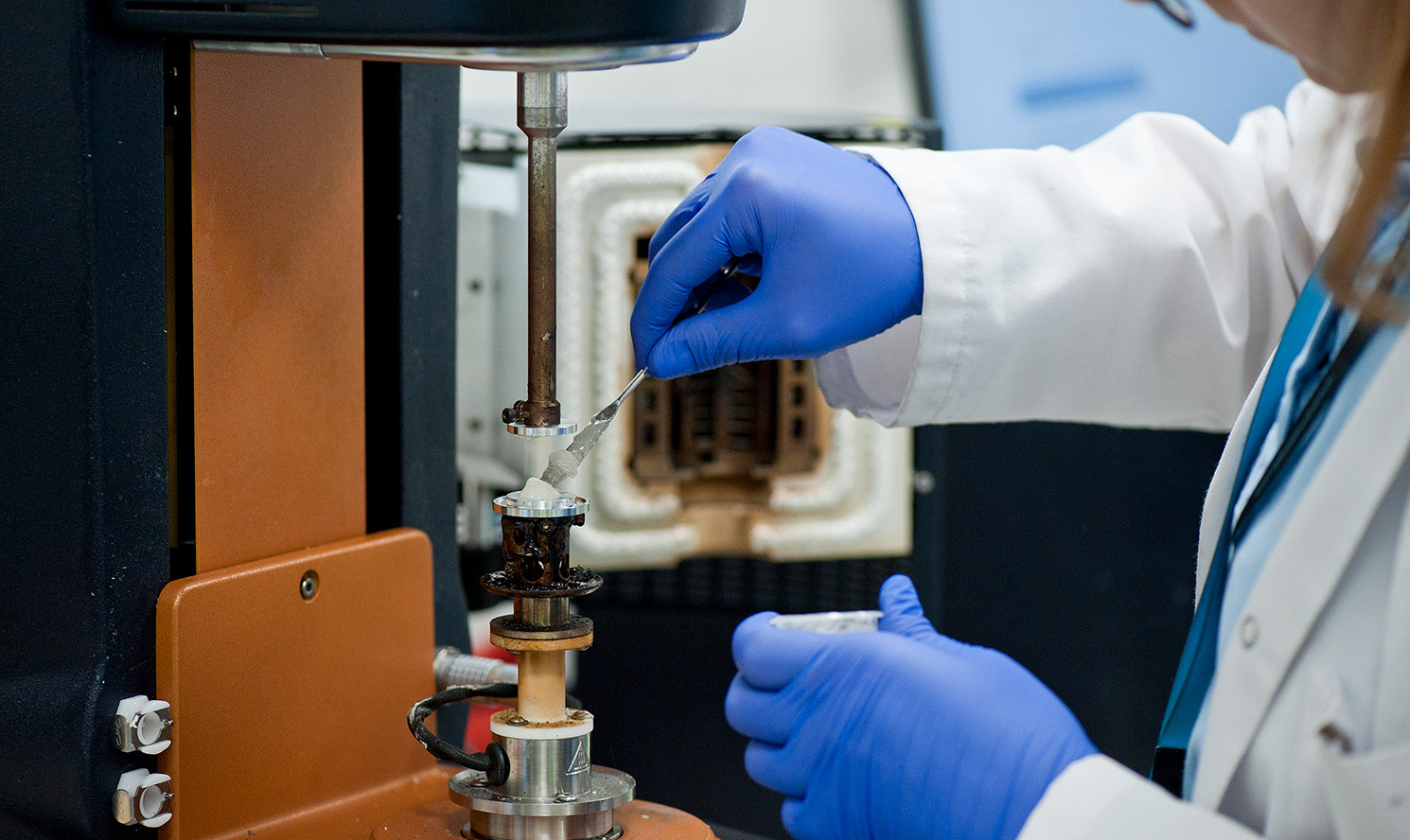

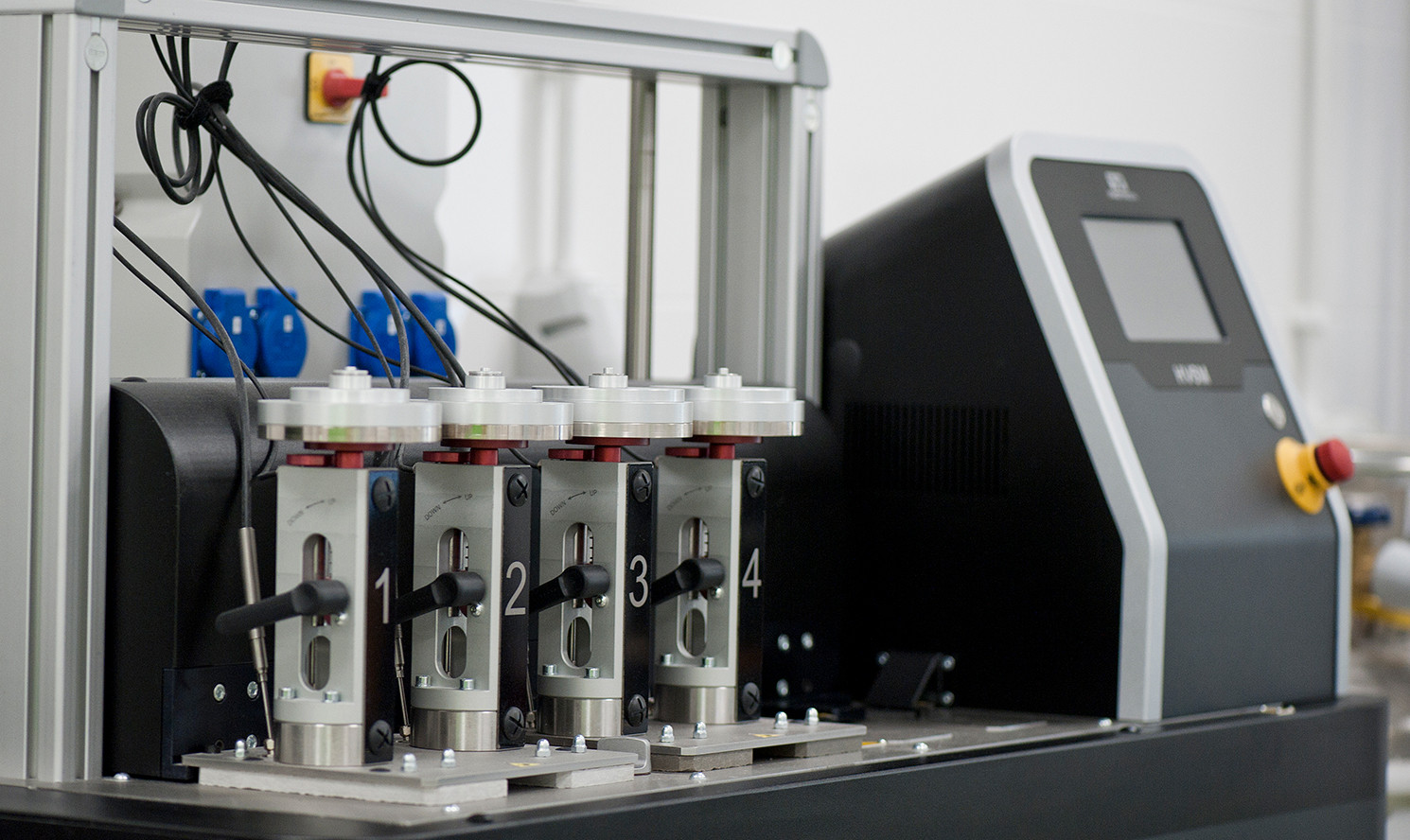

New Era Materials has a modern and very well-equipped testing laboratory. We use high-end laboratory instruments to perform a wide range of analyses according to international standards.

We specialise in polymer materials and composites testing and have extensive knowledge and highly qualified personnel in this area. We can perform basic and advanced evaluation tests including the mechanical, thermal, physico-chemical as well as desired properties of the final products, i.e. flammability, adhesion, water ingress, etc.

If you would like to find out more about the expertise of our experts, please send us an enquiry.

Laboratory Facilities

Our Capacities

thermal analisys with the following equipment:

Equipment

TGA

FTIR TG 209 F1 Libra, Netzsch

DSC

DSC 204 F1 Phoenix, Netzsch

DMA

DMA 242 E/1/G Artemis, Netzsch

HDT/Vicat

CEAST HV6M, Instron

Application

- + Thermal stability of materials under loads

- + Thermal degradation of materials

- + Glass transition and melting point of polymers

- + Mechanical and viscoelastic properties of materials

- + Heat distortion temperature

- + Vicat softening point

Our Capacities

rheological analysis according to the following equipment:

Equipment

RHEOLOGY

MCR 502 TwinDrive, Anton-Paar

Discovery HR-1, TA Instruments

VISCOSITY

Application

- + Viscosity as a function of shear stress or shear rate or temperature

- + Storage and loss modulus, G’ and G”

- + Glass transition and melting point of polymers

Our Capacities

mechanical analisys with the following equipment:

Equipment

Tensile Strength

Instron 5985, 250 kN

Fatigue Resistance

Instron 8802, 100 kN

Impact Strength

Instron CEAST 9050

Adhesion

Shimadzu AGS-X

Application

- + Tensile, bending and shear properties

- + Mode I interlaminar fracture toughness GIC

- + Floating roller peel resistance of adhesives

- + Climbing drum peel test of adhesives

- + Charpy impact properties

Our Capacities

flammability analisys with the following equipment:

Equipment

LOI

OI, FTT

Smoke Density

SDC NBC, FTT

UL-94

UL-94, FTT

Application

- + Relative flammability of plastics and composite materials

- + Specific optical density of smoke generated by materials

- + Fire hazard testing by horizontal and vertical burner tests

- + Burning behavior by oxygen index

- + FTIR toxicity measurement

Equipment

Environmental simulation

Weathering simulation

Application

- + Long-term performance of the materials

- + Resistance to environmental conditions: temperature and humidity

- + Resistance to weathering condition: sunlight and rain

Equipment

FTIR

Nicolet iS10, Thermo Fisher Scientific

Epoxide equivalent

Moisture content

Sieve analysis

Analysette 3 PRO, Fritsch

Application

- + Chemical identification

- + Epoxide equivalent

- + Moisture content by Karl Fischer

- + Quantitative particle size analysis

Our Capacities

Standard

Description

ASTM D 440

ASTM D1781 – 98(2012)

ASTM D3167 – 10(2017)

ISO 11357-1:2016

Differential scanning calorimetry (DSC) –

Part 1: General principles

ISO 11357-2:2014

Differential scanning calorimetry (DSC) –

Part 2: Determination of glass transition temperature

ISO 11357-3:2013

Differential scanning calorimetry (DSC) –

Part 3: Determination of temperature and enthalpy of melting and crystallization

ISO 11358-1:2014

Thermogravimetry (TG) of Polymers –

Part 1: General Principles

ISO 14125:2001

Determination of bedning propertis

ISO 15024:2001

Determination of mode I interlaminar fracture toughness, GIC, for unidirectionally reinforced materials

ISO 16474-1:2014

Methods of exposure to laboratory light sources –

Part 1: General guidance

ISO 16474-2:2014

Methods of exposure to laboratory light sources –

Part 2: Xenon-arc lamps

ISO 16474-3:2014

Methods of exposure to laboratory light sources –

Part 3: Fluorescent UV lamps

ISO 178:2006

Determination of flexular properties

ISO 179-1:2004

Determination of Charpy impact properties-

Part 1: Non-instrumented impact test

ISO 3001:1999

Epoxy compounds-

Determination of epoxy equivalent

ISO 306:2015

Thermoplastic materials –

Determination of Vicat Softening Temperature (VST)

ISO 3219

Polymer/resins in the liquid state or as emulsions or dispersions –

Determination of viscosity using a rotational viscosimeter with defined shear rate

ISO 4589-2:2017

Part 2: Ambient-temperature test

ISO 489-1:2016

Methods of exposure to laboratory light sources –

Part 1: General guidance

ISO 489-2:2016

Methods of exposure to laboratory light sources –

Part 2: Xenon-arc lamps

ISO 489-3:2016

Methods of exposure to laboratory light sources –

Part 3: Fluorescent UV lamps

ISO 527-1:2012

Determination of tensile properties –

Part 1: General principles

ISO 527-2:2012

Determination of tensile properties –

Part 2: Test conditions for moulding and extrusion plastics

ISO 527-3:1998

Determination of tensile properties –

Part 3: Test conditions for films and sheets

ISO 527-4:2000

Determination of tensile properties –

Part 4: Test conditions for isotropic and orthotropic fibre-reinforced plastic composites

ISO 527-5:2010

Determination of tensile properties –

Part 5: Test conditions for unidirectional fibre-reinforced plastic composites

ISO 5659-2:2017

Smoke generation –

Part 2: Determination of optical density by a single-chamber test

ISO 60695-11-10:2014

Part 11-10: Test flames –

50 W horizontal and vertical flame test methods

ISO 60695-11-20:2015

Part 11-20: Test flames –

500 W flame test methods

ISO 6721-1:2006

Determination of dynamic mechanical properties –

Part 1: General principles

ISO 6721-2:2008

Determination of dynamic mechanical properties –

Part 2: Torsion-pendulum method

ISO 75-1:2005

Determination of Temperature of Deflection Under Load –

Part 3: High-Strength Thermosetting Laminates

ISO 75-1:2013

Determination of Temperature of Deflection Under Load –

Part 1: General Test Method