Is it possible to combine excellent mechanical properties with genuine concern for the environment? At NEM, we say: definitely yes!

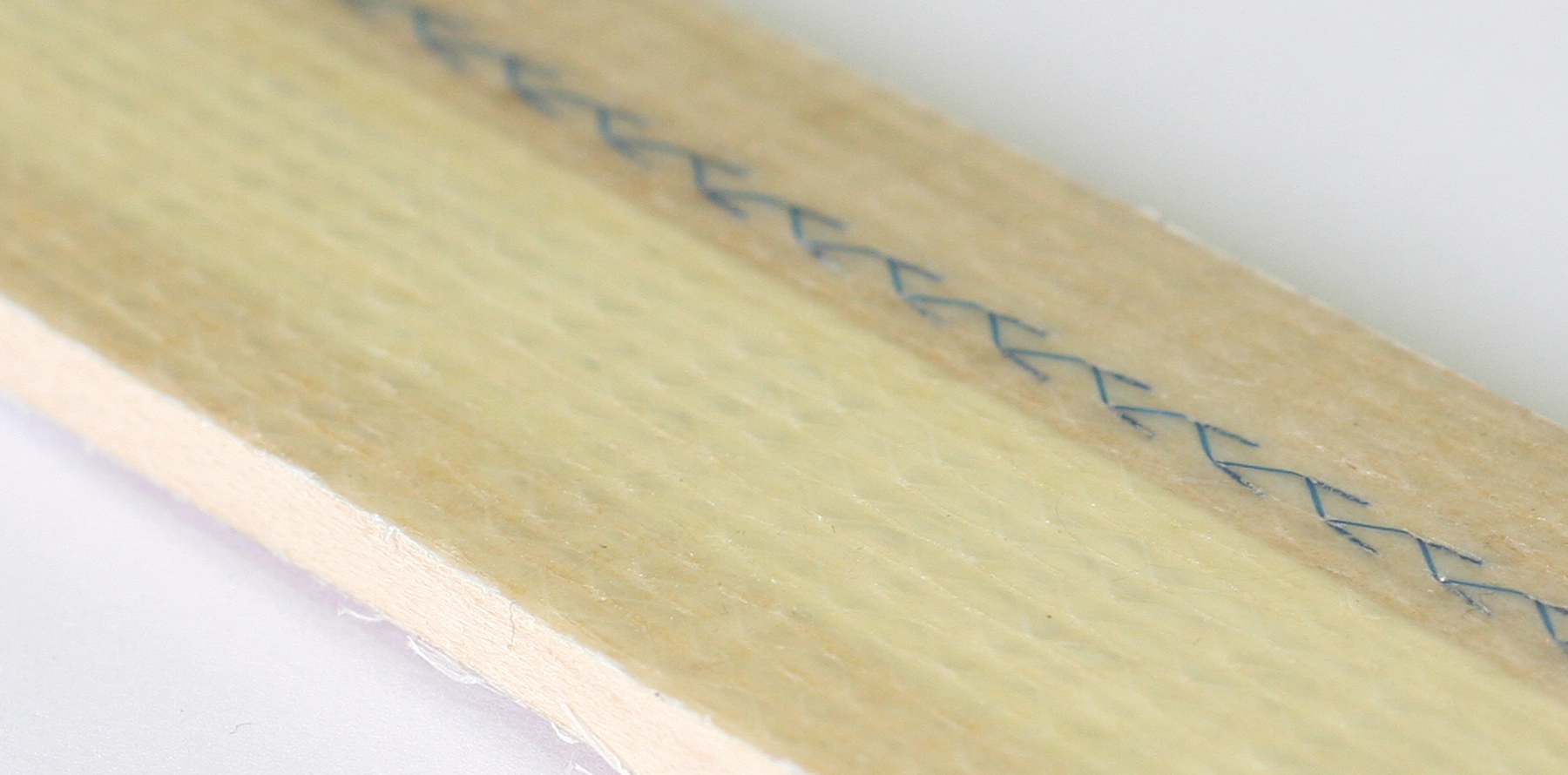

We are proud to present NEMpreg.BIO7540 – the latest product in our innovative line of BIO-prepregs, developed specifically for the sports industry. This advanced material contains at least 20% bio-based components, while offering technical performance equivalent to traditional prepregs.

BIO-resins – redefining innovation in composites

Growing market demand for reduced carbon footprints has driven us to develop a new generation of prepregs. The NEMpreg.BIO line uses BIO-resins based on renewable raw materials such as vegetable oils, lignin, algae and processed agricultural waste. This is our response to the global trend towards sustainable development, which is also evident in advanced industrial sectors.

‘Replacing traditional synthetic components with renewable and eco-friendly raw materials has been an integral part of our product strategy for several years. The creation of the NEMpreg.BIO line is both a response to market demand and a natural step forward – we wanted to offer our customers real, eco-friendly solutions that require no compromises in quality. NEMpreg.BIO7540 is proof that sustainable development can go hand in hand with advanced technology,’ says Marta Kargol, PhD, R&D Director at New Era Materials.

The launch of NEMpreg.BIO7540 is not just another product for our company – it is the beginning of a whole new chapter. A chapter in which technology meets nature and innovation is no longer a compromise between performance and responsibility. The creation of the first product in the NEMpreg.BIO family of materials confirms that we are at a milestone worth marking – like an important passage in a book that you want to return to. For us, NEMpreg.BIO7540 is just such a point – an important moment in the development of composite materials that the industry will refer to many times in the future.

For winter sports and beyond

While NEMpreg.BIO7540 was developed for applications in the ski industry, such as the manufacture of snowboards , skis and winter sports accessories, its potential is much broader. BIO-prepregs from this line can also be successfully used in the automotive, aerospace, or defense industries. Our solutions can be crucial wherever quality, lightness, strength and carbon footprint reduction are important.

Technology that already works

NEMpreg.BIO7540 is a ready-to-use product that has successfully passed application testing, is ready for commercial deployment, and can be offered on various natural or hybrid fabrics. Our advanced laboratory and production facilities enable customization of materials to meet individual customer needs while maintaining the highest quality standards.

What’s next?

We are not slowing down – our R&D team is already working on the next product in the BIO batch, this time with an even higher content of BIO components. We expect it to enter application testing in the second half of the year, opening up new opportunities for manufacturers looking for eco-friendly alternatives in advanced technologies.

NEMpreg.BIO is more than a product – it is a strategic approach to the future of composite materials.

We are looking forward to hearing from you and doing business with you. Let’s create a future based on innovation and responsibility together.

ECO FRIENDLY

INNOWATION

SUSTAINABILITY