Composite materials are playing an increasingly important role in modern defense industries especially in applications where structures must combine high strength with low weight and resistance to extreme conditions. Among these, epoxy-based prepregs stand out as key solutions. Thanks to the precisely controlled distribution of resin across the entire fabric surface, they ensure structural uniformity, predictable forming behavior, and consistent mechanical properties in finished components an essential advantage in the production of parts intended for strategic applications.

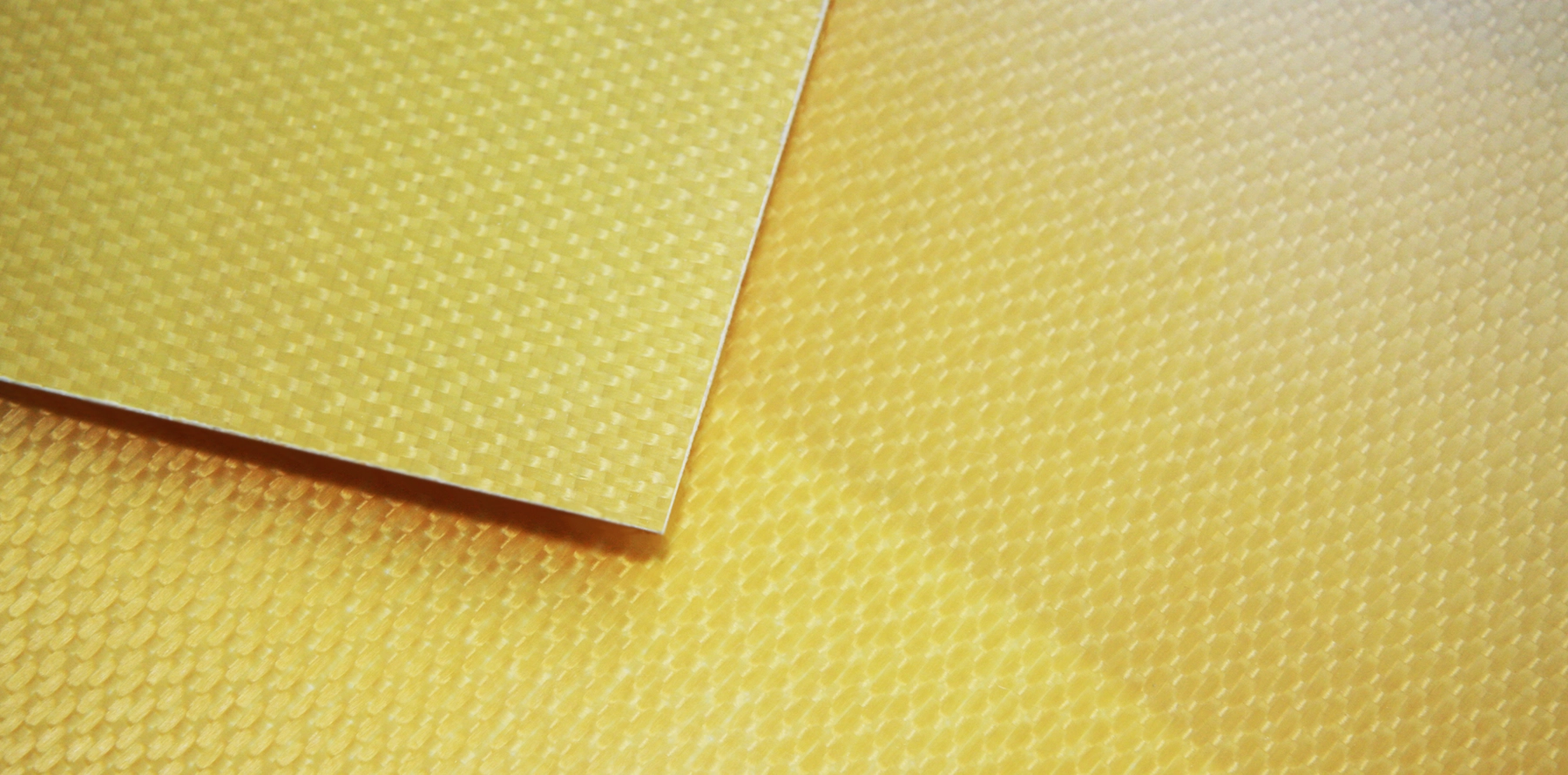

NEMpreg.UBIQ6540, reinforced with aramid fabric, is a prepreg developed for demanding applications -ranging from protective components to structural elements exposed to impact and high temperatures. By combining high-performance aramid fiber with a carefully formulated epoxy resin system, we deliver a solution tailored to the needs of the defense sector and other industries where durability, reliability, and safety are critical.

NEMpreg.UBIQ6540 has been designed for use in situations where maximum protection must be achieved with minimal weight. Its excellent impact resistance and long-term mechanical performance make it ideal for manufacturing ballistic panels, helmets, protective shields, structural reinforcements for military vehicles, and other components that require both lightness and exceptional durability.

Depending on the specific project requirements, we offer full support from the supply of NEMpreg.UBIQ6540, through technical consulting, to the production and delivery of finished composite components.

We invite you to visit our booth C05 in Hall 2 during MSPO 2025 – it’s a great opportunity to explore our aramid-based solutions and discover our full range of composite materials. If you would like to schedule a meeting in advance, please use our contact form – we’ll be happy to provide further details and answer any questions.